The very best raw materials and the ultimate care in processing guarantee exceptional quality. Florin AG sets great store by retaining its entire production process in house.

The process of extracting oil from oleaginous fruit begins with cleaning, crushing and grinding the oil seeds. Oil is then pressed from this oil-bearing material.

Essentially a distinction is made between three processes: cold pressing, hot pressing and extraction.

Oils, which are obtained by means of cold or hot pressing, are regarded as having been gently pressed. Florin AG does not employ the yield-boosting method of solvent extraction and only produces gently pressed oils.

This pressurised mechanical pressing process is identical to cold pressing, with the exception that heat is additionally applied.

Cold pressing is a purely mechanical process without the application of heat, in which the oil-bearing seed material is forced under pressure into a screw press. Cold-pressed oils are used directly as edible oils without additional processing (refining). This explains why they have a stronger odour and taste.

After pressing, oil is extracted from the oil-bearing material by spraying it with a fat solvent (hexane or benzine). The solution of oil and hexane – known as miscella – is collected and then heated, evaporating the solvent, and leaving behind the crude oil.

The remaining residue of seeds is known as oilseed meal or oilseed cake, with natural pressing, and is known as "expeller" with extraction. With all three processes, this cake, meal or expeller is rich in protein and is therefore post-processed for animal feed.

Immediately after pressing/extraction, the oils and fats are still crude and heavily contaminated with particles of seeds and shells, dyes and odorous substances and free fatty acids, and thus cannot be tolerated by the human organism.

During the next stage, refining, the crude oil is completely purified and 'refined' by removing organic and inorganic materials in a multi-stage process. Reducing these pro-oxidative substances increases the shelf life of the products, at the same time, reducing the risk of the re-formation of oxidation products.

Advantages and disadvantages of refined oils

The advantages of refined oils – over cold-pressed oils – include their higher oil yield and thus lower price and longer shelf life. Opened bottles can be used for three to six months. Refined oils have a more neutral taste and therefore have a number of different uses.

The disadvantage of refined oils: Depending on their processing, a proportion of the high-quality ingredients can be lost.

The refining process includes the following processing stages:

Spraying with hot water and the addition of citric acid removes parts of shell, sterols and lecithins (known as mucilage) from the crude oil.

These pro-oxidative substances would give the oil a bitter taste and also lead to the premature micro-bacterial decomposition of the oil/fat.

The finely distributed droplets sink down slowly, binding parts of shells and lecithins to them. The degummed water collects in the conical end of the neutraliser and can be drained off there.

Neutralisation prevents changes to the taste of the oil and extends its shelf life. Caustic soda (sodium hydroxide) is sprayed onto the surface of the oil to transform free fatty acids into water-soluble soap, which is then drained off at the conical end of the neutraliser.

During the bleaching process, metal trace elements, sterols and undesirable natural dyes are removed from the oil. The oil is first "dried", then well mixed with the bleaching clay to produce an optimum suspension to bind the quality-deteriorating particles to the bleaching clay. Finally the suspension is filtered through a plate filter and the contaminated bleaching clay is separated. The bleached oil, also known as semi-raffinate, is produced as the filtrate.

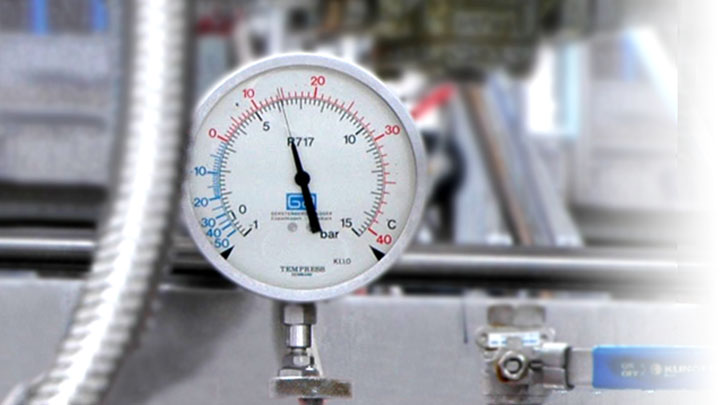

In the deodorisation process, also known as vaporisation, all the unwanted taste and odorous substances and the remaining fatty acids are removed from the oil. This process is performed at high temperatures and under vacuum.

Hot water is sprayed into the heated oil, and, as it escapes, unwanted substances, like peroxides, pollutants and other volatile substances, are carried off with it.

Refining is completed once the oil has cooled down to room temperature and been cleaned through a polishing filter.

Centrifuges are used – making use of their centrifugal force – in the production of edible fats and oils to separate the components of suspensions and emulsions.

At Florin AG, this separation process is used for the following three processes:

Winterisation is a purely physical process, in which the parts of the oil that melt at a higher temperature are separated from the main volume. Turbidity (crystals) in the oil is prevented and the winterised oil remains clear even at refrigerator temperatures.

The use of this process is restricted to oils that have a relatively low content of free fatty acids (FFA), as otherwise the loss of oil would be too great. Correspondingly, Florin AG uses dewaxing/winterisation for the production of sunflower oil and high oleic sunflower oil.

During neutralisation, the crude oil is heated to the optimum process temperature and citric acid is added to condition the non-hydrogenable phosphatides.

Additionally, diluted sodium hydroxide neutralises the free fatty acids and the phosphatides are bound with sufficient water.

The heated oil is added to the first centrifuge to separate off the soap stock. Any remaining traces of soap are removed by washing the neutral oil with hot water and are then separated from the oil in the second centrifuge. The remaining moisture is further reduced with the aid of a vacuum drier.

Citric acid is added to the crude oil, which has been heated to an optimum process temperature. After a short idle time, a proportion of the citric acid is neutralised with diluted sodium hydroxide and water is added to hydrate the phosphatides, if necessary.

Both are mixed together in the mixer and the gum is separated from the oil in a centrifuge.

As very fine particles of phosphatide cannot be separated, a specific quantity of water is added to the oil, mixed in the mixer and passed into the high-performance washing separator, which separates fine particles from the water on account of its extremely high centrifugal force.

To prevent losses of oil, this phase is returned to the first centrifuge where the fine gum particles can be separated off with the remaining phosphatides. The oil degummed in this way is then dried and further processed.

The ideal melting point of a fat is deemed to be when its solidity is guaranteed at specific temperatures.

It is possible to choose between the following three processes to change the dropping point:

Hydrogenation – also known as hardening – affects the fatty acid spectrum, which has a direct impact on the melting properties. Hydrogen is added to the oil or fat, which – with the involvement of a catalyst – transforms the unsaturated fatty acids into saturated fatty acids. This chemical transformation raises the dropping point. The more unsaturated fatty acids are converted into saturated fatty acids, the higher is the dropping point.

Melted fat is cooled down during fractionation. It forms a suspension of stearin and olein. The stearin is separated from the olein, depending on the solidity required.

In transesterification, the fatty acids are evenly distributed in the fat molecule, which also impacts its melting properties and produces homogeneous, smoother products.

Margarine is produced in a closed system under hygienic conditions.

The workflow is sub-divided into the following phases:

Refined edible oils, fats and water are mixed in a precisely defined ratio so that the end product has the precise properties required.

The solid and semi-solid fats are heated and liquefied. Lipophilic ingredients, such as vitamins and emulsifiers, are added to the fat composition.

Fat phase:

The fat phase consists of a blend of solid vegetable fats and oils and possibly smaller quantities of hardened fats/oils, which give the margarine the necessary hardness and required spreading behaviour at room temperature.

Lecithin or special emulsifiers improve the product's frying properties, carotene gives the margarine its delicate yellow appearance, natural flavouring improves its taste while vitamins improve its nutritional value.

The ingredients of the fat phase of margarine consist of sunflower oil,.rapeseed oil, palm oil, soya oil, coconut fat, palm kernel fat, lecithin, mono- and diglycerides, (emulsifiers), carotene, vitamins A, D, E, and flavourings.

Water phase::

Separately from this, water is mixed with different ingredients and traces of salt are added to further enhance the flavour and, in some cases, also citric acid to adjust the acidity level and the pleasingly fresh taste.

The ingredients for the water phase of the margarine consist of water, skimmed milk, curdled milk, salt, flavourings and citric acid. The liquid fat phase, which has been heated to 60°C and the water phase are mixed in the kettle to form an emulsion with the aid of an emulsifier. The emulsion is heated to 80°C in a pasteuriser for enhanced product safety. The liquid emulsion is then fed into the pipe cooler under high pressure.

The real heart of margarine production, the pipe cooler, comes into its own here. It consists of multiple cylinders (cooling pipes), cooled from outside, in which a shaft equipped with scraping knives rotates (crystalliser).

As it passes through the pipes cooled to minus 20°C, the mixture of the fat and water phase solidifies to form a thin layer and is then scraped off by the scraping knives.

The margarine is collected and the "crystallisation and scraping" phase repeated as often as is necessary to obtain the required product properties and desired consistency.

The margarine is then conveyed through the resting tube for between 5 and 20 minutes for further crystallisation.

It is then shaped, cut and packaged either as 1 kg or 5 kg blocks or 2 kg plates directly thereafter. The products are then stored at 10°C, 17°C or 23°C for approximately 10 days to mature. The crystals are kept larger (higher temperature) or smaller during this time, depending on the temperature. The margarine, thus produced, is then used in bakeries, kitchens or in industry.